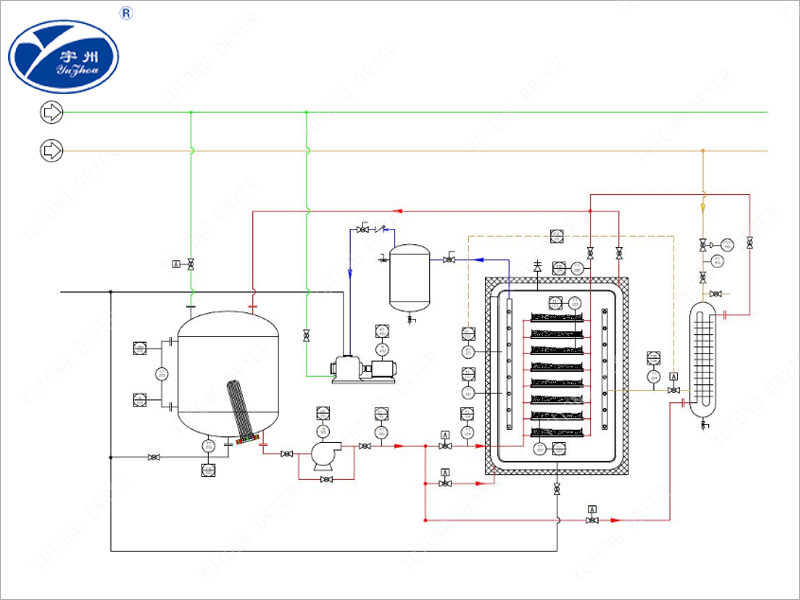

Pulse vacuum dryer is a new type of drying equipment independently developed and designed by our company based on existing product technology, which has absorbed a large amount of customer feedback and usage needs. This equipment is widely used in the pharmaceutical industry, biotechnology and other fields. It is a vacuum box drying device that complies with the new version of GMP. It is mainly aimed at drying thermosensitive materials, viscous materials, and materials that require solvent recovery. Especially for materials with high pond content, easy overflow, and easy foaming of traditional Chinese medicine extracts, its drying ability and effect are very good. This device adopts the principle of "pulse in" laminar vacuum drying, which is an efficient low-temperature drying method. It can use steam, hot water, and electricity as heat sources, and can also be equipped with saturation, circulating steam sterilization, ozone disinfection functions, online cleaning or immersion cleaning functions.

1. High drying efficiency, with an efficiency increase of over 200% compared to traditional equipment, greatly reducing drying time;

2. Compared to hot air circulation ovens, it saves over 80% in energy consumption;

3. The uniformity of the product is higher, and the quality and color of the dried product are better;

4. Equipped with online cleaning or immersion cleaning functions, with a mobile material cart design for easier cleaning;

5. For materials prone to foaming, pulse bursting design is adopted;

6. For materials that are not easy to break bubbles, an explosive drying method is adopted to fully utilize the latent heat of steam and the water absorption of undersaturated steam: a fully automatic control system is used, and the entire system is operated through a human-machine interface. Parameters can be set in sections to achieve more complex process flows, ensuring drying efficiency and effectiveness.

1. Plate layer heating: The flatness of the plate layer is ≤ 1mm, and the material tray is tightly attached to the plate layer, with high heat transfer efficiency. The hollow partition design ensures uniform heating of the plate layer, with a temperature uniformity of ± 1.5 '℃, ensuring consistent material drying;

2. The inner wall of the drying box is made of high-quality stainless steel mirror panels, with rounded corners that transition to ensure no dead corners and easy cleaning inside;

3. The inner wall is equipped with a heating layer to prevent condensation; Form an effective isolation layer, reduce the temperature difference between inside and outside, and decrease the heat loss inside the box;

4. Detachable material cart design, the material cart can be moved out of the box as a whole, making it convenient for maintenance and thorough cleaning in stages;

5. Optional condenser, which can effectively recover solvents from materials through condensation or absorption;

6. Install tempered glass doors, mirror lights, etc. on the box to facilitate observation of the dryness of objects inside the box;

7. The box door is automatically opened and closed, and the sealing strip adopts airbag sealing to ensure high vacuum inside the box.

Previous :LZG series spiral vibration dryer

Next:none!