Airflow dryer, also known as instant dryer or flash dryer, has been applied in industries such as pharmaceuticals and chemicals in China since the 1960s. At the beginning of our company's establishment, we introduced domestic and foreign technologies to provide airflow drying equipment for industries such as pharmaceuticals, chemicals, and food. For over a decade, we have continuously improved and developed the following three series of air flow dryers: QG series pulse air flow dryer, FG series tail gas circulation air flow dryer, and GFF series reinforced air flow dryer.

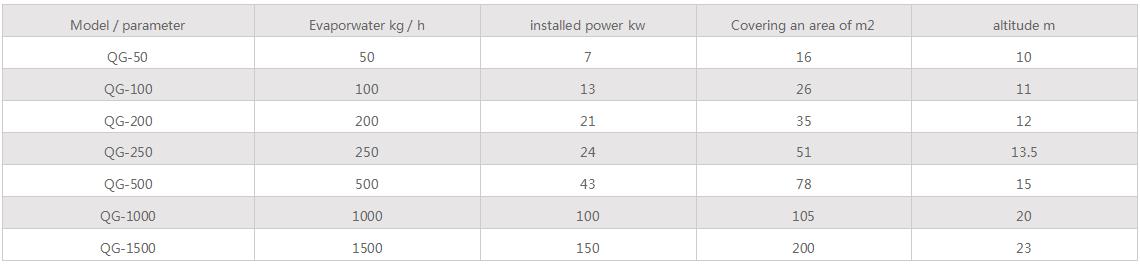

1, drying strength, equipment investment, evaporation capacity, from 50kg?H2O/h ~ 2000kg?H2O/h.

2, short drying time, suitable for heat-sensitive materials, finished products do not contact with the outside world, good quality.

3, the equipment is provided in complete sets, the heat source can choose steam heating or supporting the use of coal, oil, gas hot blast stove, etc.

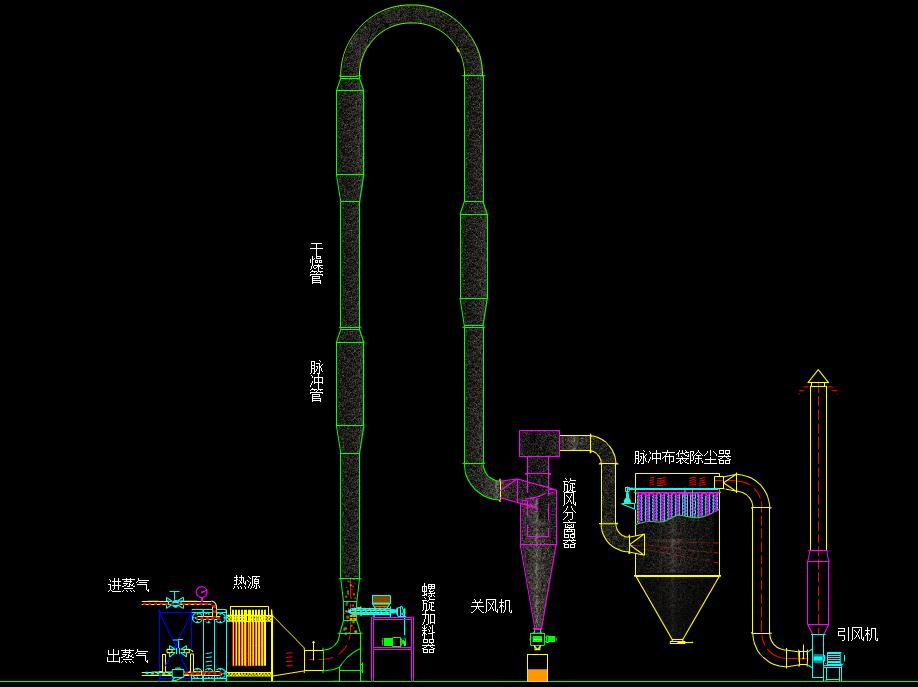

QG series pulsed air dryer is a large batch of drying equipment, it uses the principle of instant drying, the use of hot air rapid movement, drive wet materials, so that wet materials suspended in the hot air, which strengthens the entire drying process, improve the heat and mass transfer rate, through the air drying material, unbound moisture can be almost all removed (such as: The feed water content of starch and other materials is less than 40%, and the finished product can be 13.5%), and the dried materials will not cause deterioration, and the output is significantly higher than that of the general dryer, and the user can achieve higher economic benefits in the short term.

Our company produces and manufactures QG airflow drying equipment, which has introduced American technology and equipment. After special design, it has reached an innovative level. This product has a high degree of automation, low investment, low energy consumption, occupies less manpower and factory space, and has a wide range of applications.

QG airflow dryer is suitable for drying and dehumidifying powdered materials in industries such as pharmaceuticals, chemicals, food, building materials, plastics, etc., such as starch, fish meal, salt, distiller's grains, feed, gluten, plastic resin, mineral powder, coal powder, sugar chloric acid, A ? S ? C benzoic acid, 2 ? 3 ? acid, polyvinyl chloride, sodium sulfate, sodium metabisulfite and other materials.

Our company provides external consultation on airflow drying equipment and designs and manufactures non-standard airflow dryers on behalf of others.

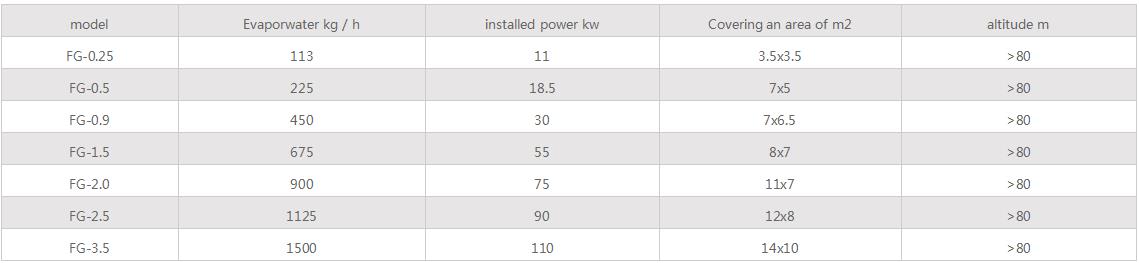

FG series air dryer has the advantages of tail gas recycling, energy saving than the general air dryer, suitable for non-viscous, loose materials, the finished products are particles and powder.

The working principle of the FG series dryer is to divide the drying of wet materials into two steps. The raw materials are first subjected to a first stage positive pressure drying using a mixture of exhaust gas from the second stage drying and supplementary hot air. The high-temperature and low humidity exhaust gas after use is discharged outside the machine, and the dried semi-finished product is subjected to a second stage negative pressure drying using fresh hot air. Dry finished products are measured and packaged. The used high-temperature and low humidity exhaust gas is used for primary drying, thus completing a good cycle drying process. The amount of supplementary hot air can be adjusted as needed, making the machine widely applicable.

This equipment is widely used for drying powdered and granular materials in industries such as food, chemical, pharmaceutical, and building materials. The products that have been dried using this series include starch, glucose, fish powder, sugar, sugar, wine troughs, feed, gluten, plastic resin, coal powder, dyes, etc.

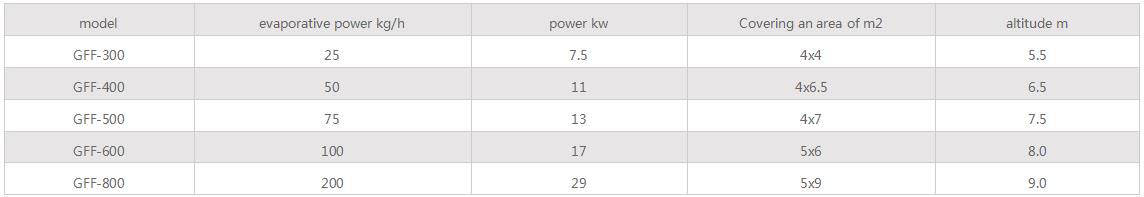

The GFF series airflow dryer is equipped with a strengthened crushing device, which has the characteristics of low final moisture content, small equipment footprint, and low height. It is suitable for filter cake, paste like, sticky, and powder like products.

Suitable for drying and dehumidifying powdered materials in industries such as pharmaceuticals, chemicals, food, building materials, plastics, etc., such as starch, fish meal, salt, distiller's grains, feed, gluten, plastic resin, mineral powder, coal powder, sugar chloric acid, A ? S ? C benzoic acid, 2 ? 3 ? acid, polyvinyl chloride, sodium sulfate, sodium metabisulfite, etc.

This machine is particularly suitable for processing wet materials with high moisture content in paste like form, as well as materials that cannot be dried by other airflow drying methods. It is suitable for filter cakes, paste like products with certain viscosity, and products that require powder as the final product.

Previous :SXG series rotary flash dryer