Application customer

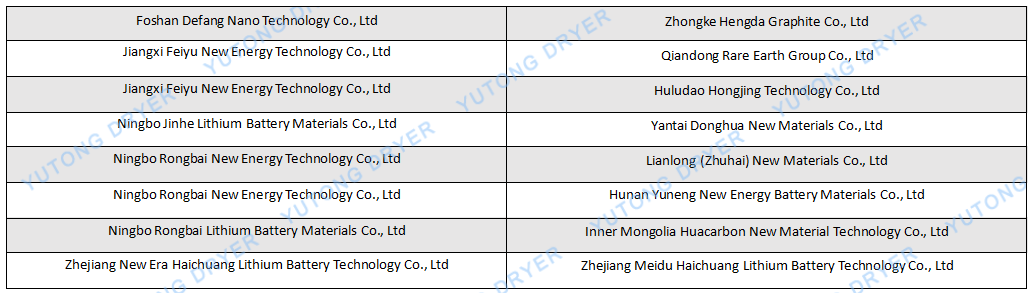

Hefei Guoxuan Hi-tech, Ningbo Moxi Technology, Hubei Wanrun New Materials, Ningde New Energy, Sichuan Xingneng New Materials, Inner Mongolia Guhua Carbon New Materials Technology, Shenzhen Yineng New materials, Xiangyang Huahong New Materials, Foshan Defang Nano new Materials

1. disc dryer for ternary precursor (nickel cobalt manganese hydroxide)

a. This type of disc dryer can dry the material with moisture content of 10%-15% to less than 0.5%.

b. Due to the thixotropy of the material, we designed a special screw conveyor before the disc dryer to realize the controllable conveying of the disc dry feed through the frequency conversion screw.

c. In terms of material, the contact part of the equipment and the material is made of 316L or titanium material.

d. In order to minimize the friction between metal and metal, our company adopts high-performance non-metallic wear-resistant blade, and the connection between the rake blade and the rake rod is isolated with tetrafluoroidal sleeve.

2. Disk dryer for lithium carbonate

a. This type of disc dryer can dry the material with moisture content of 10~15% to 0.2~0.4%.

b. Due to loose powder, but poor fluidity, high temperature resistance. To solve this problem, our company added a crushing device in the dryer.

c. In terms of material, the contact part between the equipment and the material is made of 316L material.

d. In order to minimize the friction between metal and metal, our company adopts high-performance non-metallic wear-resistant blade, and the connection between the rake blade and the rake rod is isolated with tetrafluoroidal sleeve.

3, For lithium hydroxide (single water) disc dryer

a. This type of disc dryer can dry the material with moisture content of 8% to less than 0.2%.

b. Due to the material production process and the characteristics of the material itself, the material in contact with the material is made of titanium.

c. Considering the special smell of lithium hydroxide, lithium hydroxide is generally dried by a closed disc dryer, and the tail gas needs to be treated.

PLG series disc continuous dryer On the first layer of disc dryer, the rake arm with the rake blade does rotating motion, so that the rake blade continuously turns over the material, the material flows through the surface of the drying disc along the exponential helix, and the material on the small drying disc moves to the outer edge, and falls to the outer edge of the large drying disc below. The material on the large drying tray moves in and falls from the middle to the next layer of small drying tray, and the size of the drying tray is alternately arranged up and down, so that the material can continuously flow through the whole dryer, the heating medium is fed into the hollow drying tray, and the heating medium is exported from one end to the other end, and the dried material falls to the bottom of the shell from the latter layer of drying tray, and is moved by the rake leaf to the material port and discharged. The steam evaporates out of the water is discharged by the moisture outlet set on the top, the dust is recovered by the pulse dust collector, and the tail gas is discharged out of the air by the moisture exhaust fan. Dry material discharged from the bottom can be packaged directly.

1, for the rake arm used in the lithium battery industry, the use of thick wall tube to strengthen;

2, the particle size of the battery material powder is fine, and it is very easy to fall into the bottom layer during the fall of each layer of material, and the uneven drying will make the fine powder penetrate into the bearing. In view of this situation, our company has made special improvements, adding a labyrinth seal in the middle of the last plate, so that the material on the top plate will slide smoothly into the discharge plate along the cone when it falls, and the situation of micro-powder entering the bearing will not occur;

3, the heat source of the disc dryer designed by the same industry manufacturers is a single import, the heat source in the disc has a short circuit phenomenon, and the material on the plate is not evenly heated. The design of our company is double (more) in and double (more) out, so that the heat source distribution is more uniform, and the heat absorption of the disk material is more adequate, so that the thermal efficiency is greatly improved.

4, the use of double screw feeder and with stirring arch breaking device, can ensure the continuous stability of the dryer.